Equipment use:

High rigidity single space electro-hydraulic servo universal testing machine, load range from 600kN-2000kN, suitable for steel, construction, civil engineering and other industries large load mechanical properties test。It is suitable for tensile test of metal bar and plate, tensile test of rebar steel, tensile test of steel strand, tensile bending test of high-strength bolt and high-hardness metal material, deformation of mechanical connection of steel plate, compression test of metal and concrete。

Meet the criteria:

GB/T 228 "Metal tensile test method Standard"

GB/T 16825 "Tensile testing machine test"

GB/T 7314 "Metal Compression test Method"

ISO 7500-1 "Verification of static Uniaxial testing machines"

Main features:

· High rigidity main frame, super axial and lateral rigidity, the whole machine has no gap, high coaxiality and stability;

· Bidirectional control cylinder, excellent neutral, excellent energy absorption and shock absorption performance, wide range of piston stroke;

· High precision tension and compression bidirectional load sensor, excellent lateral force resistance and super overload bearing capacity;

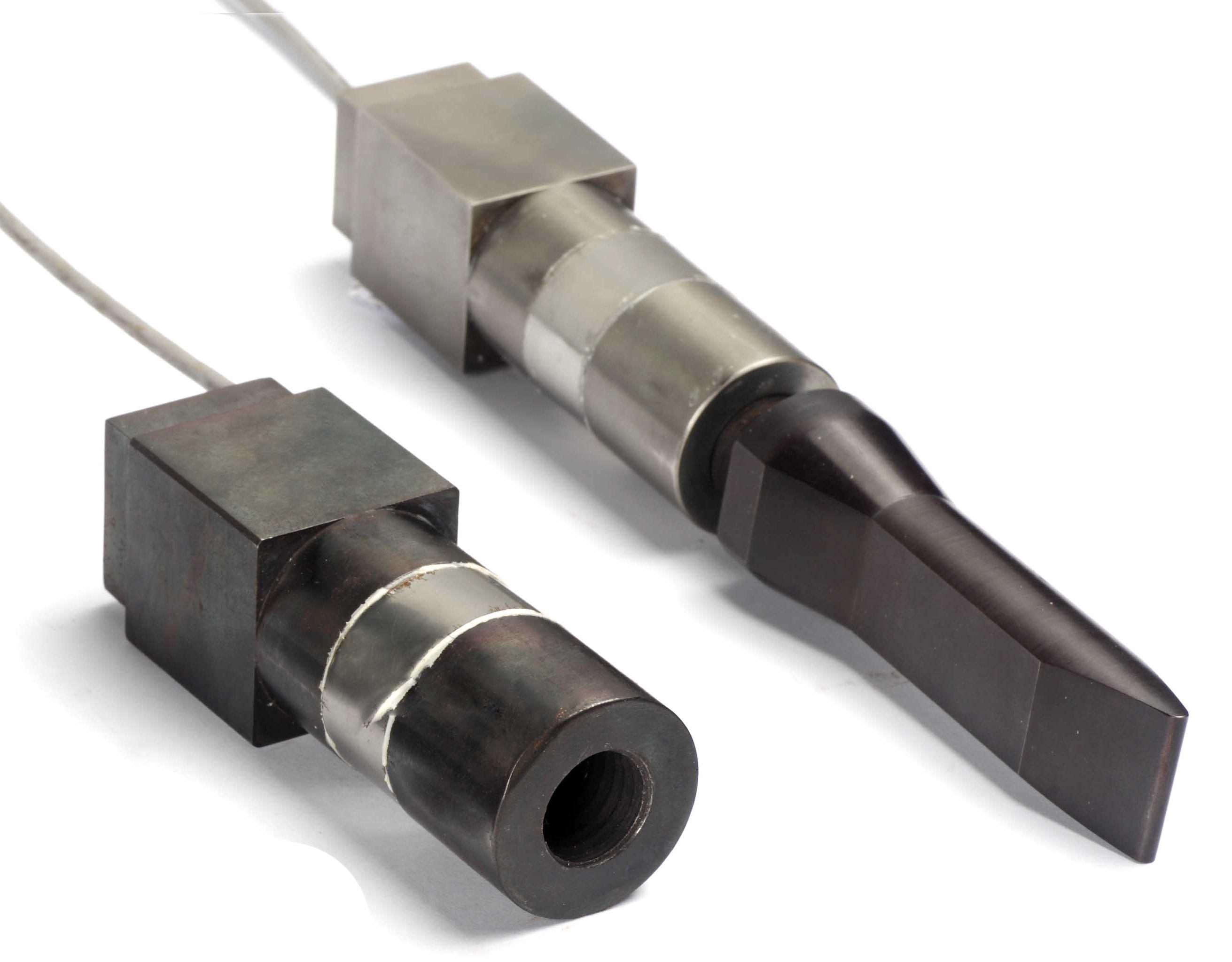

· Hydraulic wedge clamp, suitable for high strength, high hardness materials excellent clamping performance;

· The specimen clamp is made of imported alloy material, strong and wear-resistant, with adjustable clamping force;

· High-performance integrated silent oil source, using differential pressure servo technology, less heat, low energy consumption;

· Vertical test space can be customized according to customer test requirements;

· Adopt DTC-500 three-closed loop controller with international synchronous horizontal sampling frequency up to 1200Hz, the whole system has high accuracy and high reliability;

· Adopted the new version of Testpilot Pilot software developed by our company in C++ language。The software is fast and efficient, modular and open, and can be switched directly between Chinese and English.

· Microcomputer is used to control the whole test process, and real-time dynamic display of load value, displacement value, deformation value, test speed and test curve;

· Using microcomputer for data processing and analysis, the test results can be automatically saved, and the test curve can be retrieved again after the test, and the test process can be reproduced through curve traversal, or curve comparison and curve amplification;

· All Chinese test software under Windows platform, with strong data and graphics processing functions, can print out a complete test report and test curve in real time;

· With perfect limit protection, overload protection, emergency stop and other safety protection functions。

Technical parameters:

Type number TSH106D

Maximum test force 1000kN

Column configuration 4

The maximum speed of piston upward movement is 200mm/min

Piston down movement maximum speed 300mm/min

Effective distance between columns 650X400mm

Draw the maximum distance between the jaws 700mm

The maximum compression space is 485mm

The holding range of the round sample clip is ɸ12-ɸ55mm

Plate specimen holding thickness 2-40mm

Pressure plate size 200×200mm

Main machine dimensions 940×720×3250

Oil source size 850×760×1600

Total power 9kW

Weight 4500 (main engine) +500 (fuel source)